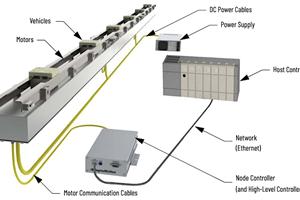

A Dutch manufacturer of pre-packed meat products has automated its in-house logistics using an IT solution from CSB-Automation and CSB-System. The new system is helping ProMessa BV meet the needs of its customers more efficiently, with a delivery performance of over 99 percent, and therefore enhance its market position. With the CSB solution, the entire materials flow at ProMessa has been automated - from packaging following production, to storage and picking, and loading onto trucks. In the past, goods and crates were moved manually, whereas today, state-of-the-art robotic technology, conveyor systems, sorters and the CSB software work seamlessly together to get the job done. The software organizes and monitors a network of machines, including two automatic crate storages, robot units, four automatic weigh labelling lines with connected sorters, a dispatch warehouse, and a conveyor system. Integrated production scheduling ensures precise tuning of workflows in terms of time and quantity. Any important details, such as up-to-date order, production and inventory data, are captured and processed in real time. This high degree of networking facilitates fast and error-free processes and enormous productivity. "We deliver a vast range of products to about 1,200 supermarkets," explains ProMessa's Managing Director Harold Rouweler. "The logistics system helps us to pick and deliver even small quantities in an efficient manner. Our customers can order any item even on short notice. Everyone who places their orders in time usually will receive the goods on the very same day," he says.