As of January 2022, Lohmann Deutschland will apply In Ovo’s gender typing technology, called Ella, in their Dorum facility to hatch chicks without chick culling. This marks In Ovo’s expansion into Germany, the first country that will enforce a ban on the culling of chicks.

Mission

Every year, 6.5 billion chicks are culled in the poultry industry. These are male and therefore don’t lay eggs. Traditionally chicks are sorted by gender by hand and the males are culled right after hatching. This has been a problem since the 1950s. In Ovo has developed the Ella machine which can identify the gender of the egg before it hatches. This enables hatcheries to only hatch the females, which is a huge improvement for animal welfare and sustainability. In Ovo is on a mission to make the Ella technology available around the world, to end chick culling altogether.

Collaboration with Lohmann Deutschland makes Ella available in Germany

As of January 2022, chicks will hatch at the Lohmann Deutschland facility in Dorum from eggs whose gender is identified by Ella. This collaboration marks In Ovo’s step to Germany, the first country in which the culling of chicks will be banned. With a capacity of 5 million hens per year, based on operation in a regular working week, Ella makes an important contribution to solving this problem in Germany. The adoption of the Ella technology by Lohmann Deutschland is a major step for In Ovo in achieving its overall mission.

Ella: complex technology to provide a simple solution

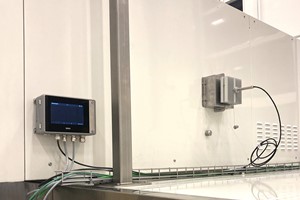

In Ovo’s Ella machine combines several high-tech innovations in the fields of sampling and analysis. Together with Demcon, an automated, high-speed process was developed in which each egg is analyzed and positioned individually to take a tiny sample at the perfect spot. Each sample is then analyzed in less than a second using the world’s fastest mass spectrometer, the Sciex Echo® MS. Combined, this delivers a fully automated solution that works inline in hatcheries, with minimal impact on existing processes.

A bright future

In Ovo is proud of the adoption of our technology by hatchery Het Anker in the Netherlands and Lohmann Deutschland in Germany and is taking steps to expand to more countries. As Ella tests on day-9 of the incubation process and works with both white and brown eggs, it’s a widely applicable technology that offers a solution to hatcheries in all markets.

Egg Processing Market size worth $ 34.5 Billion, Globally, by 2028 at 2.8% CAGR

The unprecedented COVID-19 pandemic has affected the global economy to a great extent. Considering the food industry, one of the most important sectors of the economy, a tremendous impact has been witnessed on the entire process from the field to the consumer. The restrictions in the movement of workers, closure of food production facilities, and changes in consumer demand have put excessive pressure on the food industry.

Shifting consumer preference towards processed food led to an increase in demand for high-quality egg products. Increasing demand for a nutritional diet and high protein food items led to a major increase in the Egg Processing Market.

The rise in the convenience and ease of use and storage of processed eggs is a vital factor escalating the market growth. Diminishing risks associated with contamination, and the long shelf-life of processed egg products, rise in the technological developments and advancements in egg processing machinery, rise in the demand for processed eggs that can be used as a quality protein in sports and bodybuilding, rise in the health awareness and consciousness among consumers are the major factors among others driving the Egg Processing Market. The Egg Processing Market is mainly driven by convenience, ease of use, and storage of processed eggs.

Convenience food has become more popular as the urban population grows and people's lifestyles become busier. The necessity to physically break shells and separate various components of the egg are eliminated with processed eggs. Furthermore, processed eggs are more efficiently treated and pasteurized as a result of technical improvements, ensuring safety, reduced risk of contamination, and longer shelf life. Processed eggs are commonly utilized in sports and bodybuilding as a source of high-quality protein. Furthermore, processed eggs have the potential to be used in new and unique culinary products, such as processed eggs and healthcare products. It has potential as a handy form of an ingredient in the food and beverage industry for the increasing manufacture of foodstuffs needing egg and egg components, as it substantially reduces manual labor.

Leading manufacturers of egg products are driven by a shift in consumer preference towards processed foods, rising demand for high-quality egg products, advances in egg processing technology, and increased consumer awareness in developing nations.

“With increasing demand for egg products, manufacturers are focusing on offering products enriched in proteins that are necessary for the human body. Various organizations have clearly labelled the protein percentage present in the product on the label,”

Key Takeaways from Market Study

- The U.S. is estimated to account for around 86.3% of the North American market in 2021, supported by consumer awareness regarding high nutritional content of foods and beverages.

- According to Fact.MR’s analysis, China is estimated to account for around 46.6% of the East Asia market share in 2021, driven by easy availability of raw materials and the country being the number one producer of eggs.

- The U.K. is a high-potential market in Europe, accounting for around 16.4% value share, supported by high popularity of baked goods.

- Frozen egg products are set to hold 33.2% share of the market in 2021, on the back of ease of convenience and availability.

- The food processing industry reflects 46.4% of market share in 2021, owing to high demand from the bakery industry.