In the fast-paced world of food manufacturing, efficiency, hygiene, and precision are paramount. Forpak Automation has unveiled a groundbreaking solution, LayerPak, designed to transform end-of-line production processes for products requiring stacking or paper insertion. This innovative equipment sets new benchmarks in automation, catering to the increasing demand for high-volume production in constrained spaces while maintaining stringent food safety standards.

A New Standard in Automation

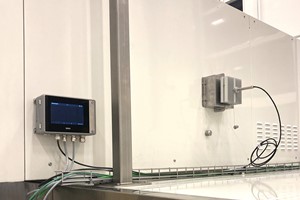

LayerPak combines advanced engineering with user-centric features to optimize production efficiency. The system integrates servo grouping, automated paper insertion, machine vision inspection, and rapid multi-layer stacking to deliver unmatched performance. Engineered for durability and ease of maintenance, LayerPak meets NSF 3A sanitary standards, ensuring it is fully compliant with industry regulations such as USDA and FDA requirements.

James Potter, President of Forpak Automation, emphasized the transformative potential of this technology: “LayerPak addresses our customers’ growing demand for automated, hygienic food production that can support high volumes in constrained spaces. It allows manufacturers to increase production speeds, significantly reduce labor costs and scrap, as well as ensure product quality. We are maniacally focused on ensuring our solutions are the easiest to operate and have paybacks of 1-2 years.”

Key Features of LayerPak

- Servo Grouping & Stacking: Precise multi-layer stacking enhances throughput and streamlines operations.

- Paper Insertion: A roll-to-sheet feeding system ensures seamless product separation, improving process efficiency.

- Machine Vision Inspection: Automated quality control reduces waste and ensures consistent product standards.

- Allen-Bradley Controls: Robust and reliable automation guarantees consistent performance.

- Hygienic Design: Stainless steel construction with full washdown capability ensures compliance with food safety protocols.

Meeting Industry Challenges

Manual stacking and interleaving are labor-intensive processes that can lead to inefficiencies, increased costs, and potential hygiene concerns. LayerPak addresses these challenges head-on, offering a mechanical, non-robotic solution that ensures faster production, lower labor requirements, and superior product quality. Its compact design makes it an ideal choice for facilities with limited space, and its customizability allows manufacturers to tailor the system to their specific needs.

Designed with the Food Industry in Mind

Forpak Automation’s commitment to innovation is evident in the LayerPak’s design and functionality. The equipment is proudly American-made and built to last, reflecting the company’s dedication to delivering high-quality, reliable solutions for the food industry. From customizable conveyor systems to advanced stacking solutions, Forpak’s equipment is engineered to optimize production lines while adhering to the strictest food safety standards.

A Game-Changer for Food Manufacturing

For food manufacturers, adopting LayerPak can result in significant operational advantages, including:

- Increased Production Speeds: Streamlined processes enable faster throughput, meeting the demands of high-volume production.

- Cost Reduction: Lower labor costs and minimized waste translate into substantial savings.

- Enhanced Food Safety: Full compliance with NSF 3A standards ensures products meet the highest hygiene standards.

LayerPak exemplifies the future of food processing equipment, offering businesses a competitive edge in a dynamic and demanding industry. Its combination of cutting-edge technology, user-friendly operation, and robust design makes it a must-have for manufacturers seeking to enhance efficiency and maintain product integrity.

For more information on LayerPak and how it can revolutionize your production processes, visit Forpak’s website.

foodHQ Staff