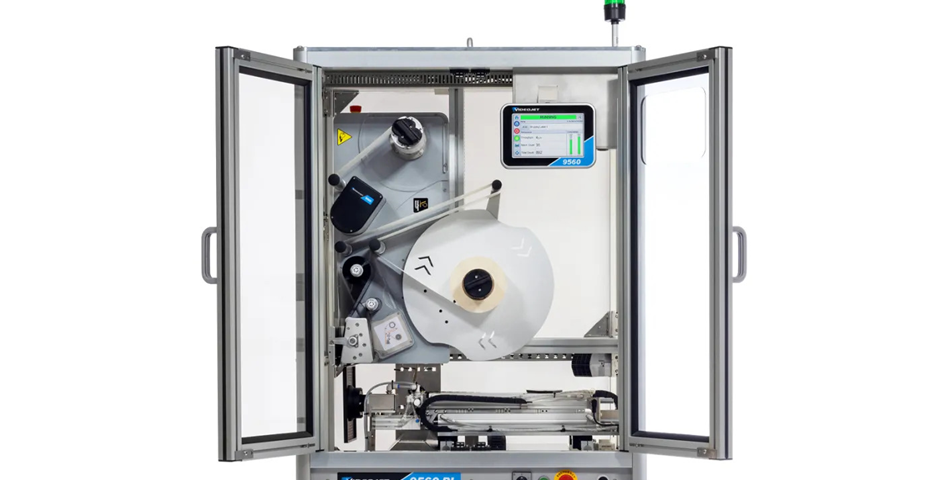

Videojet, a leading provider of coding and marking solutions, has introduced its latest innovation, the 9560 PL pallet labelling system. Designed to streamline operations and minimize errors, the 9560 PL offers a comprehensive solution for pallet labelling across various applications.

The system boasts impressive capabilities, covering up to three sides of a pallet and applying up to four labels per pallet. With the capacity to process up to 120 pallets per hour, the 9560 PL enhances productivity while ensuring accuracy in label application.

One notable feature of the 9560 PL is its ability to verify label accuracy and reprint incorrect labels as needed. Equipped with an integrated barcode scanner, the system can detect unreadable barcodes due to dead dot occurrences. In such cases, the 9560 PL automatically reprints the label and applies it over the unreadable one, ensuring compliance with industry regulations and secure warehouse management.

To meet GS1 specifications, the system applies identical 6 x 4-inch or 6 x 8-inch labels on up to three sides of a pallet. Moreover, the fully enclosed cabinet protects labels from harsh production environments, such as cold, humidity, wind, and dust, reducing unnecessary waste of label rolls.

The 9560 PL features Intelligent Motion clutchless and adjustment-free technology, enabling precise control of printing and label application. This technology minimizes logistics delays and enhances operational efficiency.

With a touchscreen interface and CLARiTY user interface technology, the system helps minimize errors and supports troubleshooting. Additionally, the option for a second GUI allows remote operation, enhancing flexibility in usage.

Measuring 900 mm x 800 mm and available in three height options, the 9560 PL offers customizable configurations to suit different warehouse setups. Wi-Fi connectivity and intelligent I/O capabilities, including standard industrial protocols, ensure seamless integration with existing systems.

In related news, Baumer hhs has unveiled a new application system that sprays anti-slip hot melt adhesive onto transport and shipping boxes, reducing plastic film consumption and packaging waste. Additionally, CONE PAL has adopted production equipment from Baumer hhs to manufacture pallets made from corrugated cardboard, minimizing cost, energy consumption, and waste while maintaining adaptability to various consumer requirements.

These developments underscore a growing emphasis on sustainability and efficiency in the logistics and packaging industries, driving innovation and transformative solutions to address evolving challenges.