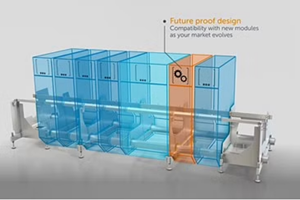

The Sacmi Group participated in the 26th edition of Plastic & Rubber Indonesia (16-19 November 2016) and presented the latest innovations in the range, from complete ultra-clean filling to cap and preform production solutions. For the group, an all-round plant engineering provider to the industry with a deep-rooted presence in Indonesia, this was a not-to-be-missed opportunity to show existing and potential customers its comprehensive solutions range, which improved even further in 2015 in terms of both production versatility and process automation. Complete, automated lines for filling PET and glass containers, cans and BAG-IN-BOX packaging. With IPS (injection preform molding) technology, Sacmi has, for some years now, been innovating the PET preform production industry through development of a platform characterized by outstanding reliability, user-friendliness and improved preform quality. Lighter and lighter, ever-better containers with applications of keen interest to the pharma and dairy industries complete the solutions range offered by the group; thanks to decades of experience and know-how developed in the closures field, the group is able to provide all the intrinsic advantages of a technology with outstanding productivity and the lowest energy consumption on the market. It was, in fact, starting from this technology that the group successfully developed innovative applications such as the new high quality, ultra-light containers obtained with CBF (compression blow forming).

Food Packaging - Bottling & Filling

Sacmi Brand Beverage & Packaging Conquers the Far East

January 2017