In an ever-evolving landscape of liquid food packaging, innovation stands as the cornerstone of progress. The pursuit of enhanced efficiency, flexibility, and hygiene standards drives industry leaders to continually push the boundaries of technology. Recently, two prominent players in the field, Syntegon Technology GmbH and KHS, have emerged with groundbreaking advancements in bottle-filling technology. Their latest offerings, the FBL filling machine from Syntegon and the aseptic block for bottle sterilization from KHS, promise to revolutionize liquid food packaging, setting new benchmarks for the industry. Syntegon's FBL filling machine, a recent addition to its Ampack portfolio, stands at the forefront of innovation. Designed for preformed HDPE, PP, and PET bottles, the FBL machine boasts unparalleled flexibility, efficiency, and hygiene standards. Its advanced neck-handling system facilitates swift bottle format changeovers, while redesigned dosing stations ensure maximum productivity without compromising product safety.

Similarly, KHS has unveiled an aseptic block for bottle sterilization, setting new standards for safety and efficiency in beverage bottling. With triple the output of conventional linear fillers, the InnoPET BloFill ACF-R aseptic block promises unparalleled performance. Automatic format changeovers and meticulous attention to hygiene further solidify KHS' position as an industry leader in beverage packaging technology.

Ampack's FBL Filling Machine: Redefining Flexibility and Hygiene

Syntegon Technology GmbH, formerly known as Bosch Packaging, has unveiled its latest addition to the Ampack portfolio – the flexible FBL filling machine. This new innovation caters to the burgeoning demand for liquid food packaging, offering a wide range of functionalities and capabilities. The FBL machine is designed to fill preformed HDPE, PP, and PET bottles, catering to volumes ranging from 50 ml to 1,500 ml. Its versatility enables it to handle a diverse array of liquid and viscous foods, including milk- and plant-based drinks, dairy products, soups, and even clinical nutrition.

One of the standout features of the FBL machine is its neck-handling system, facilitating faster bottle format changeovers. This system, adapted specifically for the FBL, allows for swift insertion of different bottle types into carrier plates, ensuring efficient transportation. Furthermore, Ampack has prioritized hygiene and maintenance, implementing an innovative concept that enhances productivity while maintaining the highest standards of cleanliness.

The dosing stations of the FBL have been redesigned to accommodate highly sensitive products, offering a low-foaming filling process to maximize output. With the capability to fill up to 36,000 bottles per hour, the FBL boasts high filling accuracy and simple handling, thanks to its SmartFill dosing concept.

Moreover, Ampack has placed a premium on product safety, designing the FBL in accordance with 3-A requirements to meet the highest hygiene standards. Its innovative tunnel design separates production and mechanics, minimizing the risk of food contamination and ensuring greater product protection.

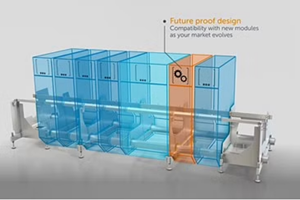

The FBL seamlessly integrates with other systems, offering complete bottle-filling lines from production to packaging. This holistic approach positions Ampack as a leader in aseptic applications, reaffirming its commitment to innovation and customer satisfaction.

KHS' Aseptic Block: Setting New Standards in Safety and Hygiene

Meanwhile, KHS, a Dortmund-based systems provider, has introduced its new aseptic block for bottle sterilization, signaling a paradigm shift in safety and hygiene standards for beverage bottlers. The rotary filler incorporated into this block offers triple the output of linear fillers, without compromising on performance or hygiene.

The InnoPET BloFill ACF-R aseptic block, equipped with a rotary Innofill PET ACF-R filler, boasts a capacity of up to 36,000 1.0-liter bottles per hour, with plans for future expansion to 48,000 500-milliliter bottles every sixty minutes. Key to its design is bottle sterilization, which eliminates all potential germs from containers prior to filling, ensuring product integrity and safety.

The aseptic filler has been meticulously redesigned to optimize hygiene standards, featuring a simplified structure with smaller stars for hydrogen peroxide supply. This innovative approach reduces consumption and maintenance costs while maintaining a high level of sterility. Additionally, the filler carousel incorporates liquid barriers to safeguard the hygiene zone from external contaminants.

A notable feature of the new rotary block is its automatic format changeovers, minimizing manual intervention and retaining internal sterility. With just a press of a button, various adjustments can be made within minutes, ensuring uninterrupted production efficiency.

In conclusion, both Syntegon Technology GmbH and KHS are spearheading innovation in liquid food packaging with their latest advancements in filling technology. The FBL filling machine from Syntegon promises unparalleled flexibility and hygiene, while KHS' aseptic block sets new standards in safety and efficiency for beverage bottlers worldwide. These developments underscore the industry's commitment to delivering high-quality products while embracing technological progress.