Fish is not just one of the staple foods in all the world's coastal regions, its high-quality constituents – from omega 3 fatty acids to iodine – mean it is also becoming a significant component of a healthy diet worldwide. On the other hand, most of the residues are disposed of or processed into cheap animal feed, although the skins do for instance contain valuable proteins.

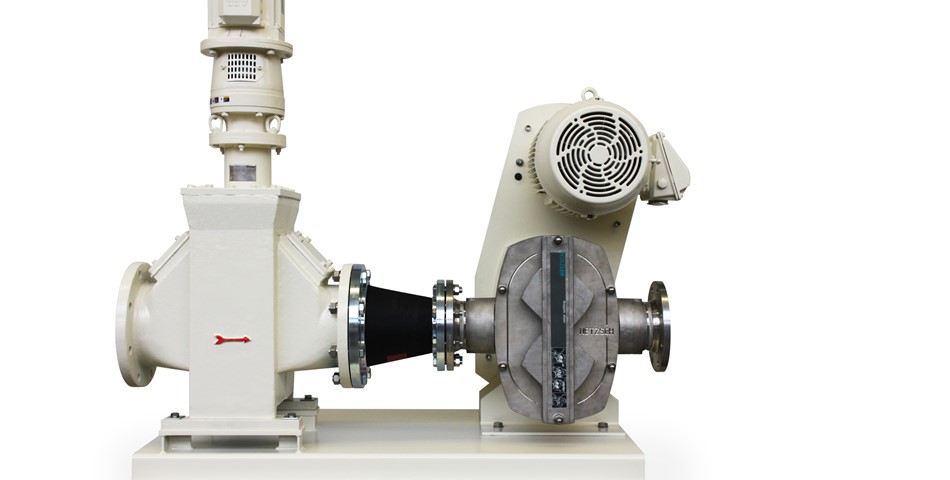

In addition to fillet production, Vinh Hoan Corp., one of the largest pangasius exporters in Vietnam, has therefore built up its own production line for collagen powder. The powder is now used in food supplements, cosmetics and pharmaceuticals. For this, NETZSCH Pumps & Systems, supplied a combination of a high-performance twin shaft macerator and a hygienic full-metal rotary lobe pump.

Vinh Hoan Corp., based in the Mekong-Delta, is one of the main global suppliers of pangasius, which is native to the region, and the company deals with customers in around 40 countries.

A key product is collagen powder with the brand name Amigen. The powder is produced by enzymatic hydrolysis from the pangasius skins derived from the production of fillets for the global market.

The fish skins are around 18 cm long, depending on the age of the fish, and also elastic and extremely slippery due to the humid environment, so the company needed suitable pump technology in order to be able to transport them for processing.

NETZSCH, the German specialist, set up a hygienic solution for this in 2015 using closed pipes and a pump, which prevents contamination of the raw material and at the same time ensures cleanliness in the production environment.