Green Plains, a leading ethanol producer in the United States, is poised to revolutionize the industry with the imminent launch of a pioneering dextrose production facility. Situated within a dry corn milling plant in Shenandoah, Iowa, the facility represents a significant advancement in ethanol production technology, promising lower capital intensity and a remarkable 40% reduction in carbon footprint compared to conventional wet milling processes.

Scheduled to commence shipments to customers in the second quarter of 2024, the facility is currently undergoing the commissioning phase after achieving mechanical completion. Anand Sundaresan, Senior Vice President of Green Plains, emphasized the transformative potential of the project, citing the innovative "clean sugar technology" developed by subsidiary Fluid Quip Technologies.

This groundbreaking technology enables the diversion of a portion of corn grind into dextrose production, offering substantial environmental and economic advantages. Sundaresan elaborated on Fluid Quip's two key technologies incorporated into the project: Maximized Stillage Co-Products (MSC) and clean sugar technology. MSC facilitates the extraction of high-value corn protein from the ethanol production process, while clean sugar technology streamlines dextrose production with lower capital and carbon intensity.

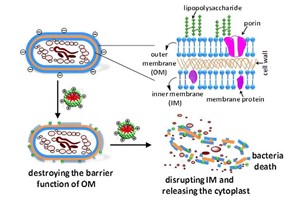

The traditional wet mill process, characterized by steeping, grinding, separation, and multiple purification steps, is bypassed in Green Plains' clean sugar process. Instead, the process entails grinding, liquefaction, fiber, oil, and protein removal, saccharification, purification, and evaporation, resulting in a simplified yet efficient production pathway. Despite forgoing some byproducts typical of wet milling, such as corn gluten meal and differentiated fiber streams, the clean sugar process ensures maximum utilization of resources, yielding ethanol, distiller’s dried grains with solubles (DDGS), and corn oil alongside dextrose.

Todd Becker, CEO of Green Plains, highlighted the burgeoning demand for dextrose across diverse industries, including food and beverage, yeasts, enzymes, biopolymers, and biopesticides. He affirmed the company's commitment to achieving food-grade certification for the facility, anticipating its attainment by the third quarter of 2024.

Moreover, the environmentally conscious approach of Green Plains' dextrose production, boasting a 40% lower carbon footprint compared to conventional methods, aligns with the sustainability objectives of many customers. With increasing corporate emphasis on reducing environmental impact and scope 3 emissions, the eco-friendly credentials of Green Plains' dextrose offer a compelling value proposition to discerning buyers.

While specific pricing details were not disclosed, Sundaresan asserted that the clean sugar technology enables cost-effective dextrose production, reinforcing the competitive edge of Green Plains in the market. Beyond the cyclical nature of ethanol demand, the stability and consistency of dextrose utilization across various sectors augur well for the company's long-term growth and profitability.

As Green Plains prepares to inaugurate its trailblazing dextrose facility, industry observers anticipate a paradigm shift in ethanol production methodologies, underscoring the pivotal role of innovation in advancing sustainability and profitability within the bioeconomy landscape.

agfundernews.com