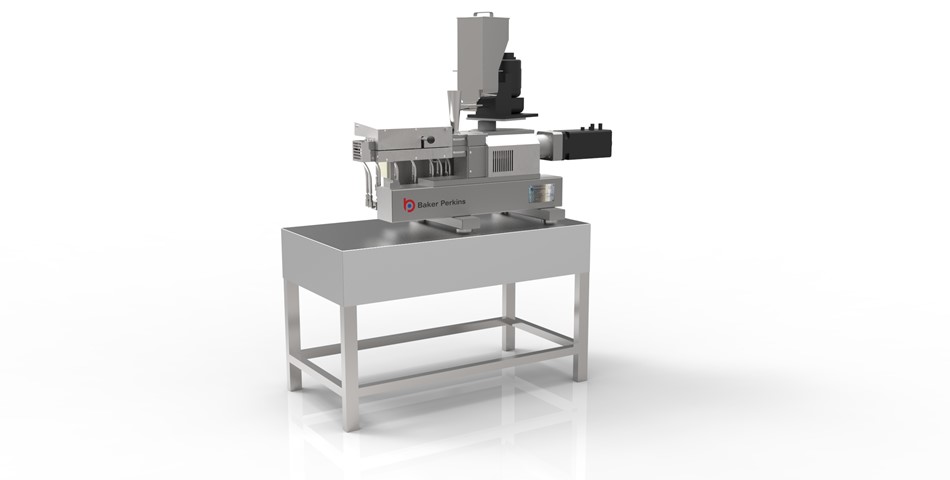

Baker Perkins has added a new version of the benchtop MPF19 to its range of twin-screw extruders for the food industry.

It provides extensive information for research and product development work in a variety of applications including snack, cereal, ingredients and pellets, with scalable geometry to Baker Perkins' range of production extruders. The MPF19 is often used as a research tool in the academic world.

The machine features the Baker Perkins clam-shell barrel. This means that the machine can be stopped at any time with immediate access to view the state of material being processed. As adjusting the formulation, process settings and screw configurations are all straightforward, and the screw configurations identical in geometry to larger extruders, the machine is an ideal tool for comparing and establishing recipe formulations.

The control panel includes most of the features found on production machines, and includes a full recipe management system holding up to 50 recipes; historical trending of data, and connectivity to a PC to capture that data. Full automatic start up and shut down sequences mirror production extruders.

Available as a fully integrated package with on-board HMI or a stand-alone unit with a separate panel, the machine provides outputs in the 5 to 25 kg/hour range. Segmented screws allow great flexibility for profile design, and splined agitator shafts maximize reliability.