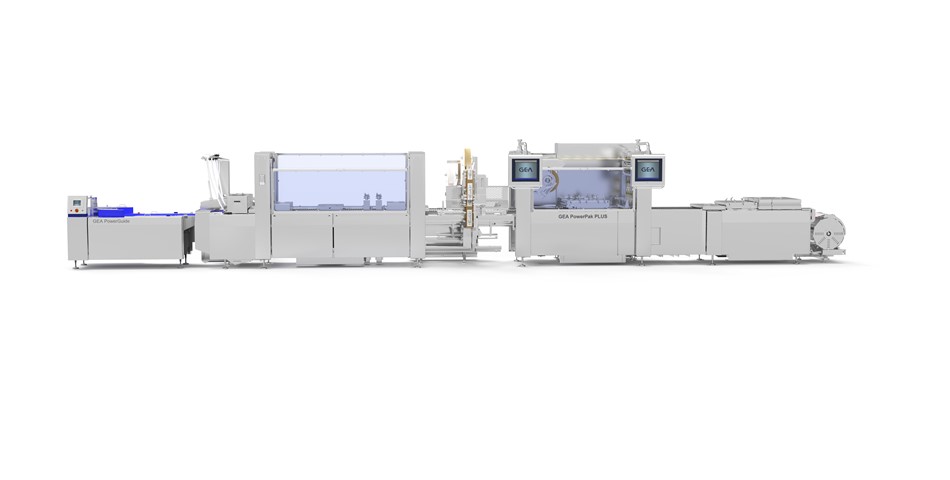

The GEA PowerPak PLUS thermoforming packaging machine lends itself to a range of different packaging solutions, including handling protection, vacuum, MAP and shrink packaging.

GEA has recently added a new dimension of versatility to the PowerPak PLUS by making it possible to use a more sustainable paper-based packaging alternative with this technology. The new packaging option is made from a moldable paper composite consisting of more than 80 percent paper and a residual amount of plastic for features that deliver barrier properties.

Thanks to technological advances, the machine can be fully relied on to safely process this delicate material. “The packaging market is currently in a state of flux,” explains Volker Sassmannshausen, Senior Product Manager Thermoforming Packaging Systems at GEA.

“While consumers and food retailers are demanding reductions in plastic usage, the food industry must ensure safe packaging from beginning to end of the supply chain. Not only must all hygiene and quality standards be met, but also legal requirements which call for a significant reduction in the amount of plastic used in packaging. When developing our machines, we always take our cues from what our customers need, so this was an obvious focus area for us.”

The GEA thermoformer ensures the highest packaging quality, efficiency and consumer convenience. Thanks to technical modifications, this packaging machine can now also easily mold coated paper. A series of functions, including those dedicated to unwinding and feeding the delicate materials as well as the newly developed multi-zone heating system, which is paired with sophisticated sealing, ensure that fresh foods are safely and hygienically packaged. In turn, solutions to simplify pack opening and material separation make it easy for consumers