INSPIRA Series

Next-generation snack food bagmakers from Ishida

A new, open-frame structure is common to all models, offering exceptional ease of access for operation and maintenance and a stability that renders most fine adjustment unnecessary. Both intermittent and rotary models benefit from new motor and drive technology that improves positional jaw control at the point of sealing.

Customer views, carefully listened to, have played a major role in the development of the Inspira range.

High-Speed Packing

The highest packing speeds: 250 bags per minute for rotary and 120 bpm for intermittent modes

Improved Accessibility

Operator productivity enhanced, with simpler access to all machine areas, improved visual management and a new human-machine interface (including 15.3” touch screen)

Automatic Adjustment

Consistent bag quality further assured by making many important adjustments automatic rather than manual, such as bag air volume, positioning of printer, N2 gas setting, and film roll centering.

Eco-Friendly

Environmental benefits: power consumption, noise levels and film waste reduced

Single-Source Supplier

From a single-source supplier with best-of-breed equipment and deep knowledge covering all phases of snack packing.

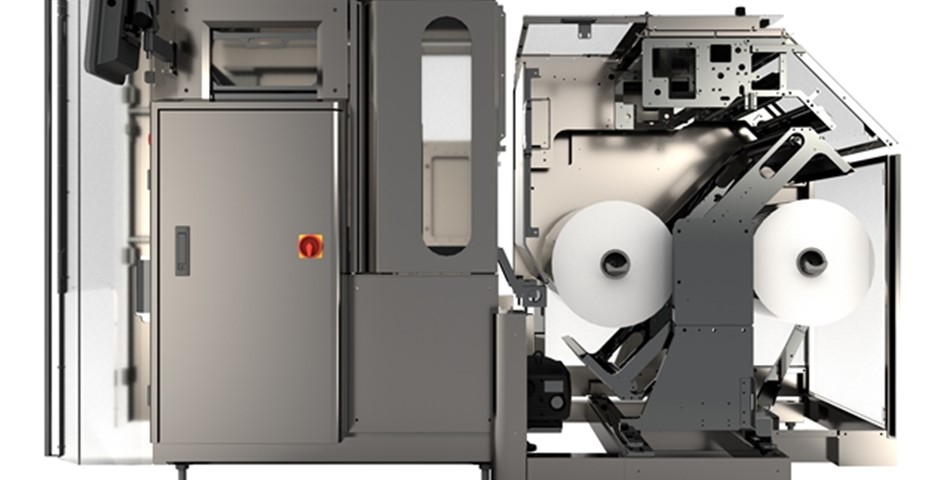

Auto splicer (Option)

Significantly reduce a down time of film change by film pattern alignment function and film positioning mechanism.

Thanks to automatic adjustment by machine, this is a user-friendly and eco-friendly option that helps prevent human error and reduce film loss.

Ishida Japan, Ishida Co. Ltd (Headquarters, Japan)

3F GRAND KYOTO

75 Nishikujo Higashihieijo-Cho, Minami-Ku, Kyoto

601-8438 Japan

Tel: +81 75 771 4141

Fax: +81 75 693 7300