A team of scientists from Nanyang Technological University, Singapore and Harvard University claims to have developed a ‘smart’ food packaging material that is biodegradable and kills microbes that are harmful to humans – all while extending the shelf-life of fresh fruit by two to three days.

The water-proof food packaging is made from a type of corn protein called zein, starch and other naturally derived biopolymers, infused with a cocktail of natural antimicrobial compounds. These include oil from thyme, a common herb used in cooking, and citric acid, which is commonly found in citrus fruits.

In lab experiments, when exposed to an increase in humidity or enzymes from harmful bacteria, the fibers in the packaging have reportedly been shown to release the natural antimicrobial compounds, killing common dangerous bacteria that contaminate food, such as E. Coli and Listeria, as well as fungi.

The packaging is designed to release the necessary miniscule amounts of antimicrobial compounds only in response to the presence of additional humidity or bacteria. This apparently ensures that the packaging can endure several exposures, and last for months.

As the compounds combat any bacteria that grow on the surface of the packaging as well as on the food product itself, the scientists say that the material has the potential to be used for a large variety of products, including ready-to-eat foods, raw meat, fruits, and vegetables.

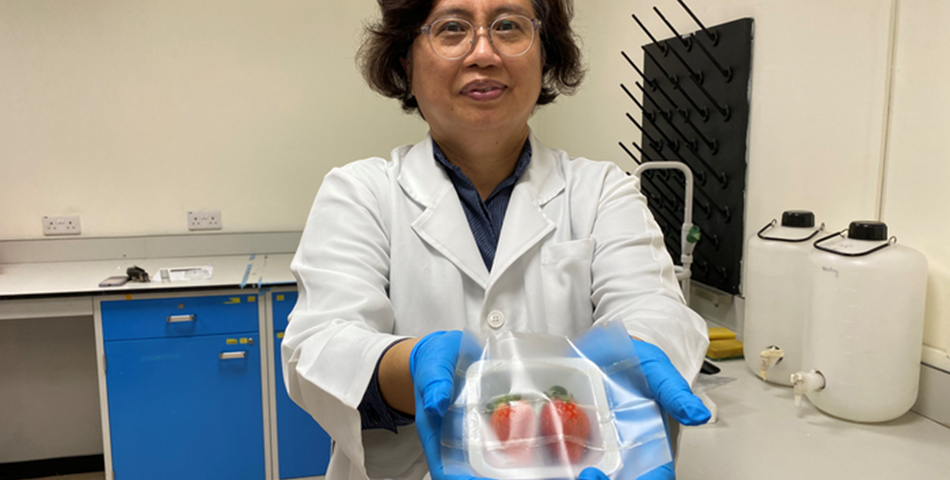

In an experiment, strawberries that were wrapped in the packaging reportedly stayed fresh for seven days before developing mould, compared to counterparts that were kept in mainstream fruit plastic boxes, which only stayed fresh for four days.

“Food safety and waste have become a major societal challenge of our times with immense public health and economic impact, which compromises food security. One of the most efficient ways to enhance food safety and reduce spoilage and waste is to develop efficient biodegradable non-toxic food packaging materials,” said Philip Demokritou, adjunct professor of environmental health at Harvard TH Chan School.

“We used nature-derived compounds to synthesise smart antimicrobial materials, which can be used not only to enhance food safety and quality, but also to eliminate the harm to the environment and health, reduce the use of non-biodegradable plastics at a global level, and promote sustainable agri-food systems.”

“Due to the globalization of the food supply and attitude shift towards a healthier lifestyle and environmentally friendly food and packaging, there is a need to develop biodegradable, non-toxic and smart/responsive materials to enhance food safety and quality. Development of scalable synthesis platforms for developing food packaging materials that are composed of nature derived, biodegradable biopolymers and nature inspired antimicrobials, coupled with stimuli triggered approaches will meet the emerging societal needs to reduce food waste and enhance food safety and quality,” added Demokritou.

“The NTU-Harvard Chan School food packaging material would serve as a sustainable solution for companies like us who want to cut down on the usage of plastic and embrace greener alternatives. As ComCrop looks to ramp up product to boost Singapore’s food production capabilities, the volume of packaging we need will increase in sync, and switching to a material such as this would help us have double the impact,” said ComCrop CEO Peter Barber.

Prof Mary Chan added: "The sustainable and biodegradable active food packaging, which has inbuilt technology to keep bacteria and fungus at bay, is of great importance to the food industry. It could serve as an environmentally friendly alternative to petroleum-based polymers used in commercial food packaging, such as plastic, which have a significant negative environmental impact."

The team of NTU and Harvard Chan School researchers hope to scale up their technology with an industrial partner, with the aim of commercialization within the next few years.

They are also currently working on developing other technologies to develop biopolymer-based smart food package materials to enhance food safety and quality.