Modular design and endless flexibility are among top customer benefits

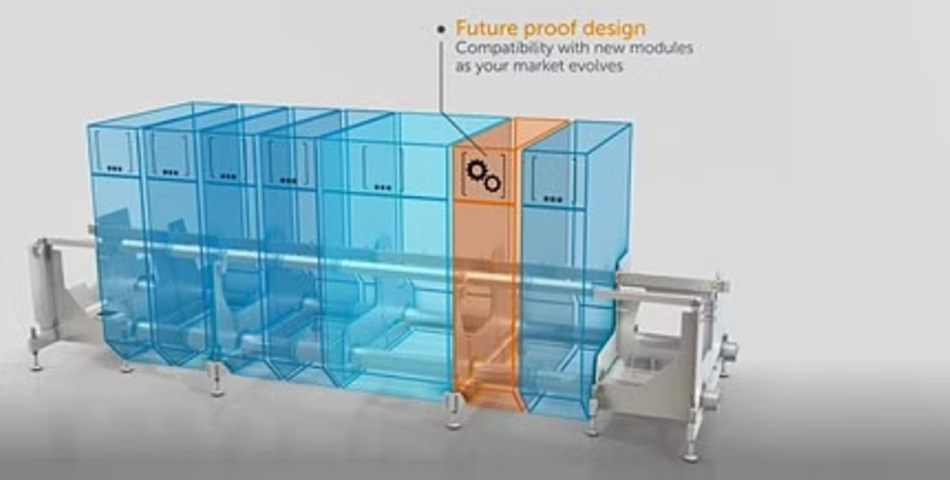

Synerlink, a leader in rigid, eco-friendly packaging solutions for the food industry, has launched Versatech, a future-proof filling solution for the food and dairy industry. Its modular design enables customers to continually realign this packaging innovation with their evolving business strategy.

“Through conversations with our customers, we discovered a market need for a filling solution that would outlast the standard 20-to-30-year lifecycle,” said François Truffier, Synerlink President. “Rather than disposing of this machine when it ceases to support the business, Synerlink’s customers can quickly, and inexpensively, reconfigure Versatech to once again work in support of new business initiatives.”

Starting with a compact 2.5-by-4-meter frame, Versatech is expandable with standard-increment modules that come in lengths of 440, 880 or 1,320 millimeters. Versatech combines that flexibility with a centralized cabling network to offer plug-and-play functionality that allows food and dairy processors to access the latest filling and packaging technologies as they become available.

“For large food and beverage processors with well-established product lines, Versatech will provide more versatility compared to other machines to test new markets, products and packaging options,” said Fabien Jégo, Synerlink Design Leader. “For smaller processors that need a machine for today’s volume and one that can scale up with their growing business, the Versatech is the perfect solution.”

In addition to its future-proof design, Versatech includes several other features that were highlighted by customers: The tubular frame shape, removeable slats and chainless design were all included to simplify maintenance and improve hygiene safety. The enhanced ergonomics of the loading station, and simplified training and troubleshooting via the HMI, address the growing issue of operator turnover.

“Today’s Versatech includes the best available technology for filling yogurt, sour cream, butter and other products in cups,” said Fabien Jégo. “In the future, this innovation will also be available for products in bottles, jars and other rigid containers, and will even be able to incorporate sustainable and hygienic packaging technologies that don’t yet exist today.”

Synerlink creates world-class solutions for cup-filling, bottle-filling, rotary electronic filling and form-fill-seal rigid packaging by bringing together some of the industry’s most trusted brands, which include Arcil, Dairy Pack and Hema. Synerlink is one of several Barry-Wehmiller companies represented in BW Packaging Systems, which brings together the collective packaging capabilities of Accraply, BW Flexible Systems, BW Integrated Systems, Pneumatic Scale Angelus and Synerlink.