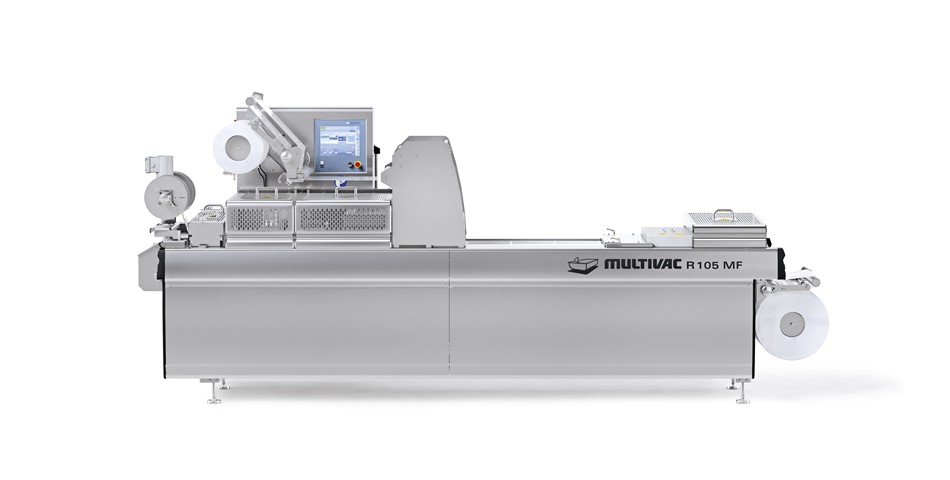

At the coming Seafood Processing Global trade fair, MULTIVAC will be putting the focus on the extended shelf life of fish and seafood and on its attractive presentation at the point of sale. The machine manufacturer from the Allg�u region of Germany will be presenting information about its products, particularly the benefits of vacuum skin packs. MultiFreshTM is a process from MULTIVAC for packing delicate food products on thermoforming packaging machines and traysealers. The upper web is tightly draped around the product and is sealed to the entire surface of the lower web. This means that even food products with sharp or hard parts, such as bones or shells, are enclosed securely and fixed in place in the pack cavity. In the traysealer sector, the company will be presenting in Brussels the fully automatic T 300 H, a high-output entry-level model for skin packing a wide range of products in small to medium-sized batches. The T 300 H is designed for a broad spectrum of tray shapes and applications due to its die construction, which enables die changes to be carried out in a very short period of time. Electric drive systems for the tray transport, lifting unit and film trim winder ensure that it has an energy-efficient method of operation. The R 105 MF thermoforming packaging machine is ideal for producing vacuum skin packs on a thermoforming packaging machine. The model is similarly designed for small to medium-sized batches, and it is equipped with integrated upper web chain guidance, which ensures that the upper web is firmly guided right into the sealing station. With its BASELINE P 605 double chamber machine, the manufacturer will be presenting at Seafood an economic model for packing products in film pouches. The P 605 offers a chamber volume of 600 x 745 x 200 mm and a pump output of up to 300 m3/h. The double-seam sever sealing ensures that a clean-looking and visually attractive pack is produced. The machine control, which is operated intuitively, makes it easy even for inexperienced personnel to operate the machine, and it ensures that the evacuation, gas flushing and sealing processes can be reproduced consistently. All the machine models on display are characterized by their simple operation, excellent pack quality and groundbreaking MULTIVAC Hygienic DesignTM. The company is one of the well-known providers worldwide of packaging solutions for food products of all types, life science and healthcare products as well as industrial items.