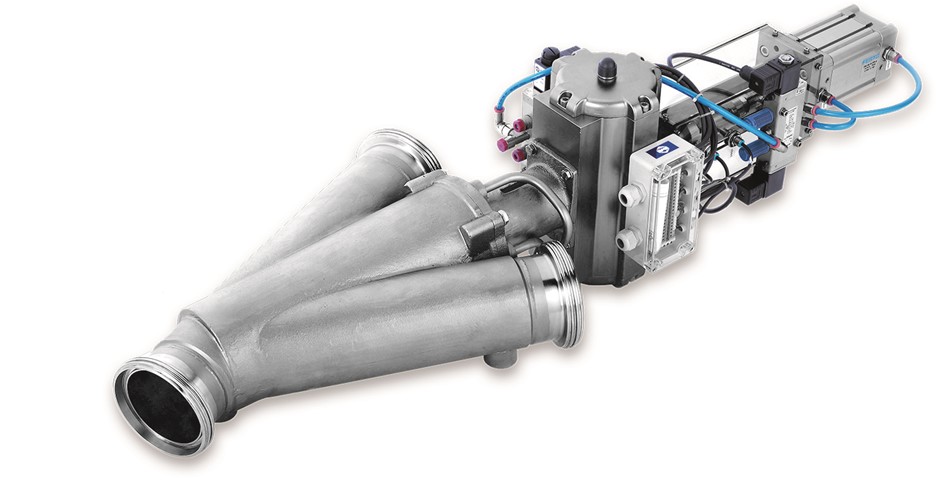

The patent-pending design of the WYK-CIP Diverter Valve incorporates an innovative retractable rotor assembly and is completely designed in accordance with European Hygienic Engineering and Design Group (EHEDG) guidelines. The valve has a true sanitary and wet cleanable design that permits the automatic cleaning of pneumatic conveying pipes. The WYK Two-Way Diverter Valve is ideally suited for inline material handling of hygienic and difficult to handle powders, such as whey powder, lactose, dried milk powders and infant formula. This valve can be used in pneumatic conveying systems, in order to divert transfer of the powder to different locations, and it is often used in return lines in spray drying applications. The fully automatic CIP (Clean-in-Place) design permits complete purging of all product residues after the automatic cleaning process without dismantling and without manual cleaning. Due to a retractable rotor assembly, the rotor can be pulled slightly out of the housing towards the rear of the valve, thus allowing the cleaning solution to rinse all product contact surfaces within the valve. In addition, specialty purge openings in the actuator plate enable an intense rinsing flow and complete discharge of the rinsing effluent. The CIP design is particularly advantageous for locations which are typically difficult to access. By significantly reducing the downtime for cleaning, the CIP concept saves both time and money. Coperion is the international specialist in compounding and extrusion systems, feeding and weighing technology, bulk materials handling systems and services.