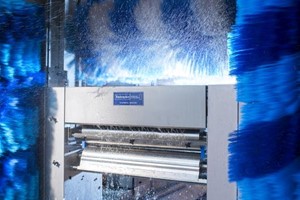

Food safety has always been paramount, never more so than in today's world where news of recalls or related illnesses circle the globe instantaneously. The resulting pressure on food manufacturers also trickles down to their equipment suppliers to pay extra attention to hygienic design. For Rademaker, however, this is nothing new. Hygienic design is and has always been at the core of innovative bakery solutions provided by the well-known manufacturer of industrial bakery production lines. At this company, hygienic design and food safety come naturally. As food safety cannot be compromised, the company offers a cross-functional approach in which hygienic design, sanitation, quality, maintenance and operations are engaged to optimize the production process. Rademaker's Sigma� design represents a combination of internally developed guidelines. It is targets the highest level of hygiene in combination with the highest operator safety whilst maintaining a perfect process technology and best possible functionality and efficiency. Therefore, this design is identified with the name Sigma� representing the sum of everything that is required for high-end industrial bakery production. More importantly the hygienically designed parts of the Sigma� guidelines are directly derived from various high-end requirements for hygiene & cleanability such as the GMA standard and EHEDG recommendations. With excellent machine surface finishing, tilted upper surfaces, rounded frames, food approved blue plastic parts and the absence of hinges and bolts, the Sigma� equipment will meet the highest industrial expectations for hygiene.