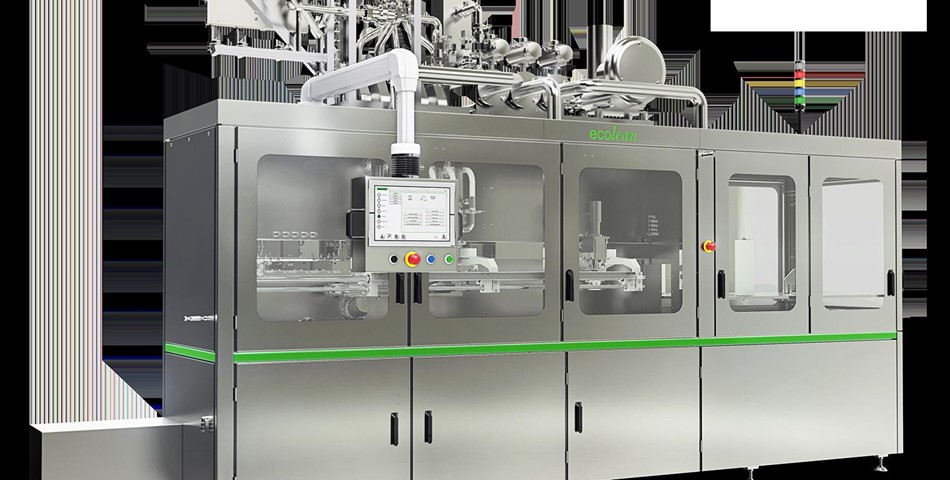

Simplified design doubles capacity, enabling customers to produce more with less. Ecolean, a global producer of lightweight packaging solutions for both ambient and chilled distribution of liquid food, announces the EL2+, an upgraded filling machine for chilled distribution portion-sized packages. The compact filling machine is another step in the company's commitment to innovation and simplicity for its customers, with a clean, modern design that doubles capacity - all in the same footprint. "Ecolean has achieved a new milestone for chilled filling machines regarding speed and hygiene," says Christian Olsson, Director Filling Line Operations. "The EL2+ will increase the competitive edge of Ecolean's packaging system in the chilled segment with a further improved ratio between speed, flexibility and hygiene, while being easy to operate." The EL2+ features five fillers and a completely redesigned servo system that uses motors instead of pneumatic cylinders so as to double capacity by reducing cycle times nearly 40% - from 2.4 seconds to 1.5 seconds. Portion-sized Ecolean� Air packages are now produced up to 12 000 packages per hour. "We optimized the design of the EL2+ to operate faster and with even more accuracy," says Olsson. "The EL2+ now uses the latest Omron control system that features a virtual master servo axis to enable optimization of machine performance. The technology was previously only used on our ambient filling machines, but the proven control system design is now available for the chilled segment with the EL2+."